南部古代型染元 蛭子屋 (有)小野染彩所は染色製品の製造販売を専門とする会社です。

Nanbukodaikatazomemoto Ebisuya Onosensaisyo

English Guide CONCEPT

English Guide

Nanbukodaikatazomemoto Ebisuya Onosensaisyo

Original Nambu Stencil Dyeing

Ebisuya

Ono Hand Dyed Fabrics

10-16 Zaimoku-cho.Morioka.Iwate.Japan

The history of old fashioned stencil dyeing can be thought of as beginning in the Muromachi Period (1336 to 1573),originating in the dyeing of family crests in the individual soldier's banners, commander's standards and "curtains" made for generals. Therefore, in each general's territory, there was stencil dyeing for that territory's individual pattern.

For

example, there are Nabeshima-gata, Shimazu-gata, Kaga-zome and

Kishu-gata patterns as well as the

pattern for the Shogun,etc.

Among these, Ebisuya, the dyers for

the Nambu family,a branch of the Takeda family, has one of the oldest

traditions,going back to Koshu-Nambu-go (Yamanashi Prefecture) where

the Nambu family originated.

The Nambu-gata patterns that came out of this tradition continue today and are called "the original Nambu-gata patterns."

In

other words, I, Nobuaki Ono,am the 18th generation, and we have an almost 400 year history.

We moved to Morioka when the

castle of Lord Nambu was built here, and we have been doing business

at our present location

for about 350 years. We can be sure of

this by consulting our family tree, which shows the 5th year of the

Kanei Period (1628).

The special characteristics of Nambu-gata

are dynamic patterns with delicate expression and graceful flow. In

short,

-1-

It

can be said that the heroic nature of the Nambu and the art loving

personalities of the Lords of Nambu Castle penetrated even to the

common people.

This work of mine is fostered by this historical

tradition and has been handed down from my ancestors.I always make an

effort to revive the wonderful styles and patterns of my ancestors.

If this is transmitted to future generations as a small light in

Japanese culture, I will be very happy.

Making

of the Stencil and Dye-proof Paste

The process of old fashioned

Nambu stencil dyeing is in short just what the words say; based on a

stencil, a paste is applied to the cloth and an undyed pattern is

left behind.

Cloth dyed in this way is of course used for

kimonos, as well as purses,card cases, noren, obi, table

centers,table cloths, various types of bags, and many other

things.

One feels the naturalness and heroic movement seen in

the gracefulness of this classic art, and may I say a unique feeling,

a nuance maybe, or something like that

that comes

out of the stencil dyeing.

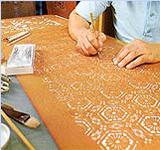

If I begin telling

how the stencils are made, I would say they start with the design.

After the design is finished, it is placed on the stencil paper, and

the pattern is cut out based on it. This is one of the most important

techniques in stencil dyeing, and it requires long training, patience

and effort.

The four stencil cutting techniques are as follows:

Tsukibori: Using

the point of the knife, the pattern is cut out by pushing the knife forward.

Nomibori:

The tip of the chisel (nomi) is a half circle. Using this tip against

the paper, a circular shape is cut out by spinning the

tool.

Dogubori: The tip of the chisel is circular, square, or

one of a number of other shapes, and that shape is formed in the

stencil by means of a stabbing motion.

Hikibori: This is also

called shimabori. A straight edge is placed on the stencil paper, and

a stripe is cut by pulling the knife towards oneself.

Besides

these, some-e (picture dyeing) techniques are among those with a long

history. In short, the picture is drawn by squeezing the dye-proof

paste out of a tube.

There

are coloring and painting techniques for the pictures, and the

pictures are

completed using them. This is one of the three

techniques for dyeing with uncolored spots that originated in the

Tempyo Period (710 to 794), and can be thought of as descending from

wax printing (batik).

At that time, beeswax is said to have been used, but in the Momoyama Period (16th century), it is said to have been replaced with a paste.

At

present, there are very few people doing this kind of dyeing, and it

is very rare.

The following is a brief explanation of the

dye-proof paste used at our factory, for your reference:

A small

amount of rice bran is added to rice

flour, and it is kneaded with the proper amount of hot water until it

becomes sticky and elastic. It is then steamed for about two

hours,and it becomes stronger and thicker. So that it does not get

too hard, a small amount of hot water is added and it is kneaded with

a stick and stored that way.

On the other hand,a proper amount of rice bran is added to a small amount of refined rice bran and mixed with the base paste that has been stored in a separate container to make the dye-proof paste.

At

that time it is important that salt be added to preserve the

softness, so the paste will not dry out and crack.

Usually a

mixture of three parts paste to two parts of the rice bran product is

thought to be proper for standard stencil dyeing. Of course,

depending on what it is used for and the fineness or coarseness of

the pattern, the amounts in the mixture must be adjusted.

Next,

here is a simple explanation of the dyeing process:

(1) Prior to

dyeing, the cloth is processed and dried so that the weaving paste

and oils in the thread are removed.

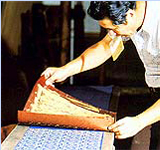

(2) The dye-proof paste is applied to the dried cloth using the stencil.

(3) Next is Jiire: Soy bean juice is applied to the material to which the paste has been applied in order to facilitate the penetration of the dye.

(4) The dye is applied with a brush, and if variation in shade is needed, accents are made with the proper dyes. After dyeing,

the piece is dried and washed to complete the

process.

However, there are many other methods, and this one is

just an example.

Mukai-zuru

(facing cranes pattern)

This is a diamond shaped pattern made

with the Mukai-zuru, the crest of Lord Nambu. This diamond shaped

crane pattern is a pattern peculiar to old fashioned Nambu stencil

dyeing.

![]()

Senba-chidori

(thousand plover pattern)

Ebisuya Sanuemon, the dyer who went to

Sannohe with Nambu Yoshimitsu, the lord of Koshu-Nambu-go, is said to

have cut out this pattern after having been fascinated by the beauty

of a flock of plover at the seaside. This is a pattern peculiar to

old fashioned Nambu stencil dyeing.

![]()

Nambu

Hagi (Nambu Japanese bush clover pattern)

This is thought to be

the oldest Nambu stencil dyeing pattern.

One can see the

beautiful flow of lines within a disorderly pattern.

![]()

"Nanbukodaikatazomemoto Ebisuya Onosensaisyo”

Zipcode-jp 020-0063

10-16 Zaimoku-cho .Morioka.Iwate..Japan

SITE TOP

バナースペース

南部古代型染元 蛭子屋

(有)小野染彩所

Nanbukodaikatazomemoto

Ebisuya Onosensaisyo

020-0063

岩手県盛岡市材木町10-16

Zipcode-jp 020-0063

10-16 zaimoku-cho,morioka-shi,

iwate-ken,japan

E-mail

info@katazome.jp

offical-website

https://katazome.jp